Textile preparation

Scouring and desizing

It is the process through which the sizing agent used during the weaving process is removed, as well as removing the natural impurities of the cotton.

Chemical whitening

Once the scouring and desizing processes have been carried out on the fabrics, they need to be subjected to a final process to remove the dirtiness that has not been removed in previous processes.

At TEXIA FINISHING we use hydrogen peroxide and caustic soda that give the fabric a sufficient degree of whiteness for later processes of dyeing and printing.

Mercerizing

It is the process through which the characteristics of the cotton fibre are modified with caustic soda achieving greater hydrophilicity, resistance, shine, pilling and easiness to iron, dimensional stability and efficiency in the later dyeing and printing processes.

We recommend this treatment whenever the composition of the fabric is mainly cotton.

Optical whitening

It is the process through which cotton or polyester optics are incorporated onto the fabric, previously prepared, to obtain a maximum degree of whiteness.

Textile finishes

Chemical Finishes

Through the application of chemical products the fabric is provided with different mechanical properties during its use, such as the touch, fall, and body. At TEXIA FINISHING we undertake the following chemical processes of textile finishes:

Teflon coating: the Teflon coating works against staining on water and oil bases (hydrophobic and oleophobic).

Softening: this type of finish gives a soft touch to the fabric and gives it more fall in order to be able to adapt to the required needs.

Priming: priming is a process the aim of which is to give a touch with more body to the fabrics and with more stiffness.

Easy wear: this finish gives properties to the textile articles so that they can be washed with suitable domestic treatments and once dry are ready for use without the need to iron them.

Easy care: this technology provides the fabric with the capacity to reject stains, avoiding their absorption and making later cleaning of the fabric easier.

Mechanical Finishes

Mechanical finishing techniques afford changes in the physical characteristics of the fabrics (for example, texture, density, hardness, width, etc.). At TEXIA FINISHING we undertake the following mechanical processes of textile finishes:

Sanforising: sanforising fabrics enables a controlled shrinkage so that it remains as stable as possible and does not have “high” shrinkages later in the washing machine. It gives more fall to the fabric (touch).

Calender: this type of finish gives the fabric a soft touch, smooth and shiny on the surface.

Tumbler: with this finish we achieve an aged appearance of the fabric, maintaining all the properties.

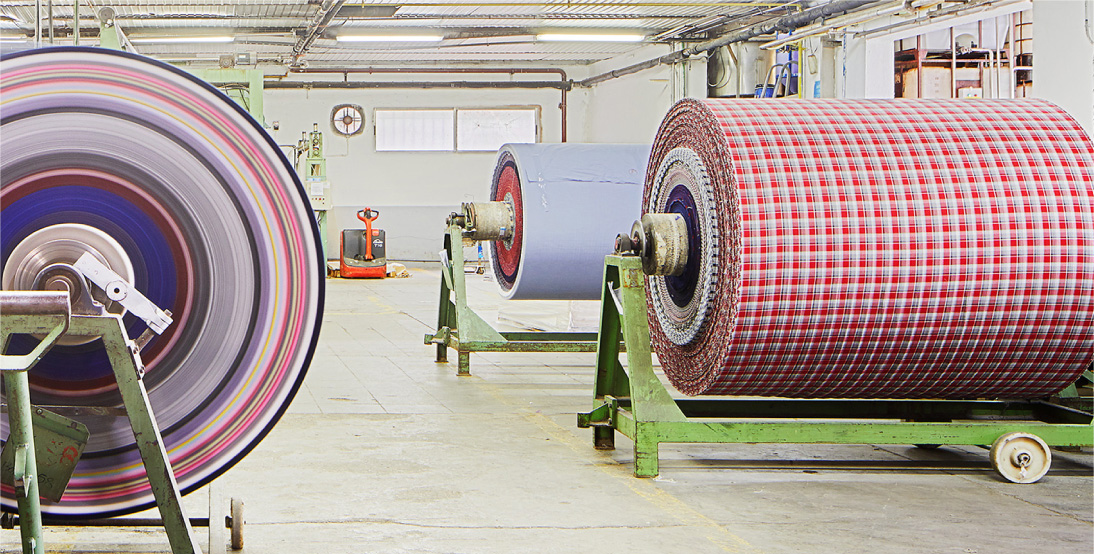

Printed textiles

We have rotary printers, of 3 and 4 colors. Both printers can print simultaneously on both sides, in 1 or 2 colors respectively.

Two-sided printing enables us to be unique in the sector. This unique technology enables us to develop differentiated designs. As an example, we are capable of imitating dyed-yarn shirt-making, obtaining major advantages in logistics and costs.

Dyed textiles

At TEXIA FINISHING we undertake a dyeing process applied by continuous foulard with pigments. The pigment is ideal for pale and medium colours for children’s garments.

Excellent resistance to light, rubbing wet and dry and can be washed with bleach.

R+D+I

As collaborators we develop technological and industrial processes and those of new products for third parties. As an example, we develop our own products, which we commercialise through 3 of our own brands: ROLLDRAP, MY DRAP and DAY DRAP. Unique products in the market with a major coverage.